RS-50

Low global warming & higher efficiency replacement for R404A

RS-50 has a Global Warming Potential (GWP) of less than one half of R404A together with a higher efficiency which delivers energy savings and a lower contribution to global warming.

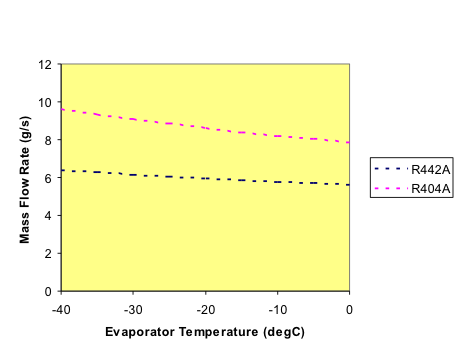

RS-50 can be used to replace R404A in both new & existing equipment. Mass flow of RS-50 is lower than R404A so that reducing the opening of the expansion device may be required. No changes to other hardware are necessary. A significant increase in energy efficiency compared to R404A and R507 can be expected. Users will achieve a lower carbon footprint due to the lower direct GWP of the refrigerant & its inherent higher efficiency.

Replacement for R22 in refrigeration applications

RS-50 is a non ozone depleting and non flammable replacement for R22 in medium and low temperature refrigeration applications. The efficiency and cooling capacity of RS-50 provide a close match for R22 in overall system performance. Flow rate is identical to R22 which avoids the need to change or alter existing pipework.

Performance Characteristics

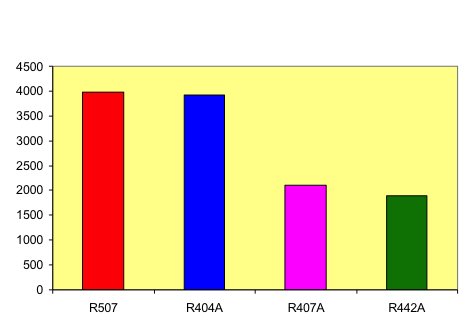

- Global Warming Potential less than half of R404A & R507

- Suitable in OEM & retrofit applications

- ASHRAE safety classification of A1

- Higher Coefficient of Performance than R404A & R507

- Higher capacity than R404A, R507 & R22

- Effective at medium and low temperatures

- Good match for R22 in refrigeration applications

- Mass flow equivalent to R22 and considerably lower than R404A & R507

- Zero Ozone Depletion Potential

- Non flammable & low toxicity

Applications

Because the properties of RS-50 are similar to R404A & R507, it is suitable for use in many of the applications where R404A & R507 are commonly found including supermarket display cases, cold stores, freezers, refrigerated transport, ice machines, cold storage, transportation of foodstuffs, freezer cabinets, beer cellars, freeze dryers & environmental test chambers.

R22 is also used in many of these refrigeration applications where RS-50 can be a suitable replacement.

Lubricants

RS-50 is compatible with the same (POE) lubricants which are commonly used with R404A & R507 so that there is no need to change the oil when converting from R404A & R507 to RS-50. When replacing R22 with RS-50, the lubricant should be changed to a polyol ester oil.

Safety

RS-50 is non flammable under all conditions of fractionation as per ASHRAE Standard 34. The components of RS-50 have been subjected to toxicity tests carried out by Alternative Fluorocarbons Environmental Acceptability Study (AFEAS), and have been declared to be of low toxicity. RS-50 has been designated a refrigerant number of R442A by the ASHRAE with a safety classification of A1.

Servicing

Because RS-50 is a blend, it should be charged into the system in the liquid as opposed to vapour form. There is no need to make hardware changes when converting from R404A & R507 to RS-50 other than reducing the opening of the expansion device. Because RS-50 has a similar flow rate to R22, there is not need to adjust or change the expansion device during a retrofit.

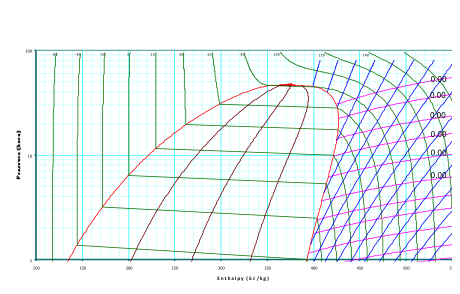

Physical Properties

| Property | RS-50 | R404A | R22 | |

|---|---|---|---|---|

| Molecular weight | 81.8 | 97.6 | 86.5 | |

| Boiling point (1 atm) | °C | -46.5(1) | -46.2(1) | -40.8(1) |

| °F | -51.61(1) | -51.21(1) | -41.5(1) | |

| Temperature Glide | K | 4.6 | 0.5 | 0 |

| Critical Temperature | °C | 82.4 | 72.1 | 96.1 |

| °F | 180.3 | 161.7 | 205.1 | |

| Critical Pressure | bara | 47.6 | 37.3 | 49.9 |

| psia | 690 | 541 | 724 | |

| Liquid Density (25°C) | kg/m3 | 1108 | 1044 | 1191 |

| Density of saturated vapour (25°C) | kg/m3 | 47.7 | 65.3 | 44.2 |

| Latent Heat of Vaporisation at boiling point | kJ/kg | 266(1) | 200(1) | 234 |

| Cv (25°C & 1bara) | kJ/kg.K | 0.727 | 0.784 | 0.559 |

| Cp (25°C & 1bara) | kJ/kg.K | 0.838 | 0.877 | 0.662 |

| Cp/Cv (25°C & 1 bara) | 1.152 | 1.118 | 1.185 | |

| Vapour Pressure (25°C) | bara | 13.3(1) | 12.6(1) | 10.4 |

| psia | 192(1) | 182(1) | 151 | |

| Vapour Viscosity (25°C & 1 bara) | cP | 0.0126 | 0.0120 | 0.0126 |

| Liquid Viscosity (25°C) | cP | 0.141 | 0.128 | 0.164 |

| Liquid Thermal Conductivity (25°C) | W/m.K | 0.0857 | 0.0636 | 0.0835 |

| Surface Tension (25°C) | N/m | 0.00661 | 0.00455 | 0.00808 |

| Specific heat of liquid (25°C) | kJ/kg.K | 1.58 | 1.54 | 1.26 |

| Ozone Depletion Potential | ODP | 0 | 0 | 0.055 |

| Flammability limit in air (1 atm) | vol% | none | none | none |

| Inhalation exposure (8 hour day & 40 hour week) | ppm | 1000 | 1000 | 1000 |

(1) Bubble point